Abstract

Carbon capture from hard-to-abate industries is essential. This study investigates the effect of stripper pressure on the performance of amine-based CO2 capture from cement flue gas, using the CESAR1 solvent. Through a rigorous data filtering and binning methodology, experimental results were systematically categorized, enabling a precise evaluation of how stripper pressure and stripping intensity affect solvent regeneration, thermal efficiency, and subsequent energy demands. Additionally, a holistic analysis of operating with altered stripper pressure is presented, where downstream compression and solvent degradation are considered. Increasing stripper pressure consistently improves capture efficiency, reduces lean solvent loading, and increases the cyclic capacity, ultimately leading to lower specific reboiler duty.

Higher stripper pressure also enhances lean-rich heat exchanger performance by improving temperature differentials. Operating at higher pressure reduces the water load on the overhead condenser, even at elevated temperatures. These conditions, in turn, mitigate overall cooling duties. Elevated stripper pressure decreases both reboiler duty and compression work. From our results, operating at higher pressures does not present downsides. However, degradation rates increase at elevated temperatures. We suggest that the standard operating pressure for capturing CO2 with the CESAR1 solvent be evaluated, as it provides an opportunity for reduced energy consumption while also monitoring solvent health over extended periods.

Keywords: CO2 capture, CESAR1, Advanced configurations, Pilot-scale

Authors: Isaac Appelquist Løge, Can Demir, Sai Hema Bhavya Vinjarapu, Randi Neerup, Ebbe Hauge Jensen, Jens Kristian Jørsboe, Maria Dimitriadi, Vanja Buvik, Halil Halilov, Carsten Fritzner Frøstrup, Istvan Gyorbiro, Nomiki Kottaki, Asams Nelliparambil Jayan, Søren Jensen, Jakob Lindkvist Karlsson, Philip Loldrup Fosbøl.

Publication – Development of a Validated Rate-Based Model

Abstract In this work, we developed a new e-NRTL thermodynamic framework for CO2 absorption in aqueous mixtures of 2-amino-2-methyl-1-propanol (AMP)…

New Publication: Aerosol Modeling in CO2 absorption using CESAR1

We are proud to announce that Hallvard F. Svendsen, Hanna K. Knuutila, Ardi Hartono, Maxime Francois and Diego Morlando at…

Thermodynamic Properties of CO₂ Absorption in CESAR1 — Essential Data for Better Process Modelling

We are proud to announce a new scientific publication from the AURORA project, authored by Diego Morlando, Ardi Hartono and…

Journal Publication – In-Depth Study of CESAR1 Solvent Degradation Under CO₂ Capture Conditions

A new scientific publication based on research from the AURORA project has just been released in the journal Industrial &…

Conference publication – GHGT-17: Viscosity and Density data for the CESAR1 solvent

Abstract Global warming is a major issue that needs to be addressed and limited. The CESAR1 solvent blend has a…

Conference publication – GHGT-17: “Storage potential evaluation of eastern Mediterranean area as final step of the full chainassessment”

The final step in capturing and storing carbon dioxide (CO₂) emissions is geological storage, where CO₂ is injected deep underground…

Understanding Solvent Degradation in CO₂ Capture – CESAR1 Solvent Degradation in Pilot and Laboratory Scale

The fight against climate change requires innovative solutions, and one promising method is CO₂ capture and storage (CCS). CCS involves…

Turning Waste Into Opportunity: Thermal Reclamation Chemistry of Common Amine Solvents

CO2 capture technology is vital for reducing greenhouse gas emissions. But what happens when the chemicals used in this process…

Closing Knowledge Gaps – Density and Viscosity of Unloaded and CO2-loaded Aqueous AMP-PZ blends

AURORA’s latest scientific journal publication provides experimental density and viscosity data on different unloaded and CO2-loaded aqueous blends of 2-amino-2-methyl-1-propanol…

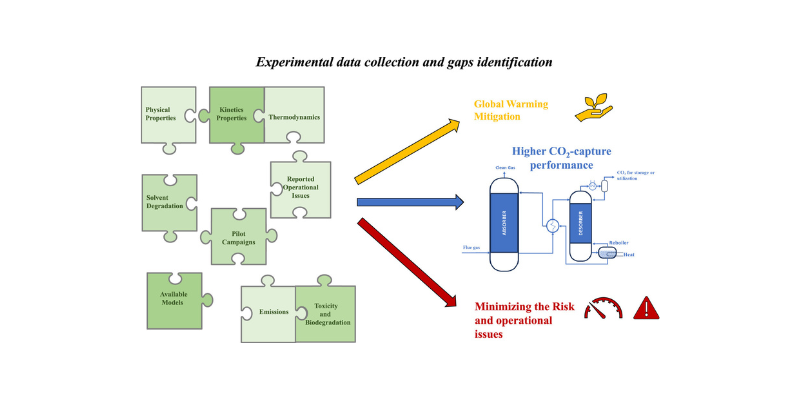

Unlocking New Potential of CESAR1-based chemical absorption Technology: Available data and knowledge gaps of the CESAR1 solvent system

AURORA latest review paper, developed in collaboration with researchers from SINTEF and NTNU, provides a comprehensive analysis of the CESAR1…